- Home

- Knowledge center

- Blog

- 4 ways your warehouse can support sustainability supply chain management

Blog

4 WAYS YOUR WAREHOUSE CAN SUPPORT SUSTAINABILITY SUPPLY CHAIN MANAGEMENT

The United Nations estimates1 that in 2050, the world´s population could come close to 10 billion. If we were to maintain our current lifestyles, this would require the equivalent of almost three planets in resources2. It´s not hard to see that our production and consumption patterns are becoming increasingly unsustainable, leading governments, investors, businesses, and the public to place sustainability at the top of their agendas.

In this blog post, we will take a closer look at the sustainable supply chain, why it matters, its focus areas, and what actions you can take in the warehouse to support sustainability supply chain management.

What is meant by a sustainable supply chain?

A sustainable supply chain considers the financial, social, and environmental impacts of supply chain operations. Sustainable supply chain management takes a holistic approach to sustainability, starting from product design through raw materials sourcing to reverse logistics processes, and considers all stakeholders involved in or affected by operating the supply chain, such as investors, suppliers, employees, customers, and local communities. It implements initiatives and responsible practices that address global issues - e.g., climate change, human rights violations, and corruption - in supply chains.

Why is supply chain sustainability important?

According to McKinsey3, over 80% of greenhouse-gas emissions generated by consumer companies are embedded in their supply chains. Manufacturing is energy-intensive and requires extraction of raw materials while transporting products around the world accounts for 7% of global CO2 emissions4. On the other hand, supply chains often span continents - companies outsource certain activities to suppliers far from their headquarters, making it difficult to monitor compliance with human rights, labor conditions, ethics standards, environmental measures, etc.

Businesses can significantly influence global sustainability efforts by improving their supply chain sustainability, for example, by using more recycled materials in the production stage instead of raw materials or by carrying out more rigorous audits of supplier sustainability.

Several external sources provide guidance and sustainable supply chain management frameworks, such as the UN Global Compact and the Global Reporting Initiative (GRI).

What are the 3 elements of supply chain sustainability?

The term “triple bottom line” (TBL) was created by John Elkington5, a business advisor and environmental activist, in 1994. The concept argues that a business operation's social and environmental elements are just as essential as the financial aspects and that there are three bottom lines to a company's success: people, planet, and profit. Consequently, businesses should treat these three elements as the ultimate goals of supply chain sustainability and evaluate their performance based on their achievements in these areas.

Supply chain sustainability examples - 4 actions you can take in the warehouse

So, what is the role of warehouse management in supply chain sustainability? The key is to use what you have more thoughtfully, cut the resources needed to run your warehouse, and create a healthy and safe work environment for your employees. Here are 4 ways a Warehouse Management System (WMS) can help your efforts:

-

Reduce your carbon footprint by optimizing yard movements

The WMS provides full visibility and control of what is happening at the gates, parking lots, and docks so that you can avoid congestion and long waiting times at the yard. One of our customers uses its WMS with yard management on 10 warehouse sites. After implementing the function, they have reduced their annual CO2 emissions by 87 tons at one site alone and have saved over €150,000 in resources compared to pre-launch.

-

Pick smarter to cut the amount of returns

According to research6, returns account for 15m tons of CO2 emissions annually. Some of them occur by delivering the wrong product to customers. The WMS helps avoid unnecessary returns by improving the accuracy of picking through better control by smart scanning or RFID control and extra verification during the picking process.

-

Save energy & resources by optimizing your pick routes

Using Artificial Intelligence (AI), a WMS can calculate the shortest pick routes and can cut the transport distance within the warehouse by more than 20%. This saves energy and reduces wear and tear on trucks, extending the lifespan of your equipment.

-

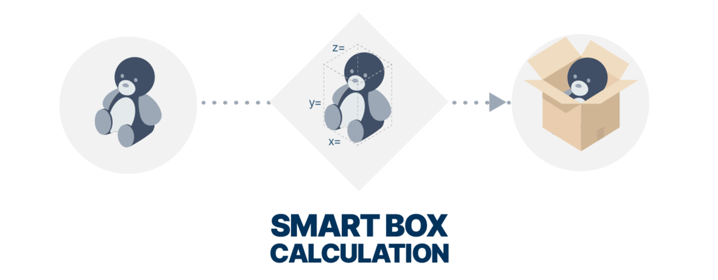

Reduce waste with smart box calculation

Did you know that 30% of packages contain unnecessary air?7 With the help of AI, the WMS selects the optimal packaging for each shipment, considering not only the dimensions but the cost of the material and transport. Your benefits? Better resource management, less amount of waste, and elevated customer experience.

Are you shipping unnecessary air?

Take our digital test to find out if you are shipping unnecessary air. The results will show how much you can improve your warehouse management operations and how to become more sustainable.

Sources

- https://population.un.org/wpp/Publications/Files/WPP2019_Highlights.pdf

- https://www.un.org/sustainabledevelopment/sustainable-consumption-production/

- https://www.mckinsey.com/capabilities/sustainability/our-insights/starting-at-the-source-sustainability-in-supply-chain

- https://www.itf-oecd.org/sites/default/files/docs/cop-pdf-06.pdf

- https://hbr.org/2018/06/25-years-ago-i-coined-the-phrase-triple-bottom-line-heres-why-im-giving-up-on-it

- https://warehousenews.co.uk/2021/08/the-environmental-impact-of-ecommerce-product-returns/

- https://www.ehandel.se/postnord-ska-leda-kampen-mot-paketluft-vi-har-ett-ansvar