- Home

- Knowledge center

- Blog

- What is a wcs system? (warehouse control system)

Blog

WHAT IS A WCS SYSTEM? (WAREHOUSE CONTROL SYSTEM)

What is a WCS system? The definition

A Warehouse Control System (WCS) is software that coordinates and controls automated equipment in a warehouse—such as cranes, conveyors, and picking systems. It acts as the real-time decision-making engine that ensures smooth material flow, load balancing, and integration across all automation systems.

Automation is an important part of the modern warehouse. It ensures stable performance in a fast-paced economy, handles omnichannel distribution tasks with speed and flexibility, and can tackle labor shortages. But successful automation is not just about investing in the right equipment – you also need a warehouse control system (WCS) to optimize processes and act as a messenger to the machinery.

This blog post will discuss what a WCS system is and how it ensures you get the most out of your warehouse automation solution.

So, what is a Warehouse Control System (WCS)?

It is a software application designed to manage how tasks are performed by the goods handling automation equipment in the warehouse, such as cranes, picking stations, AGVs, and so on. Think of it as a police officer directing traffic at a busy intersection – it handles the complex decision logic for how the different automation solutions should work together. Its main tasks are the following:- Connection to automation equipment

- Routing in automated areas

- Orchestrating automated solutions

- Flow control

- Load balancing

- User interaction

- Priority handling within automated areas

- Exception handling

- System monitoring

When do I need a warehouse control system?

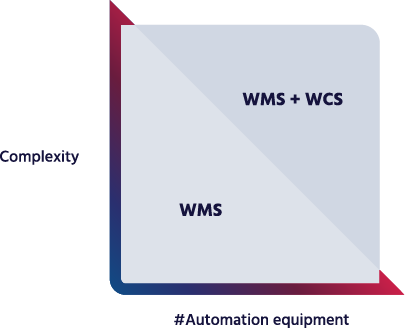

It depends on two factors:

1 | The level of automation in your warehouse

2 | The complexity of your warehouse automation solution itself

If you have primarily manual processes with some non-complex automation, your warehouse management system could be enough to control that. But as you add more automation machinery to your operation, the number of different vendors and systems will grow in your warehouse. At one point, there will be too many of them for you to monitor, let alone control, to work together efficiently. That´s where a WCS system comes to your rescue providing seamless integration of all automation systems.

The bottom line is, do not wait until you are in a state of “islands of automation.” It can damage operations and prolong the return on your automation investment.

What should I consider when selecting a warehouse control system?

In a supply chain industry that is constantly disrupted, your ability to change and be flexible increases your resilience. Your warehouse control system must support this. Check the following aspects:

-

Flexibility:

Your WCS should have a plug-in architecture that integrates with all types of automation equipment and suppliers, so you are free to choose the automation solution you need to grow your business today and in the future.

-

Full integration with your WMS:

It could be beneficial to have your WCS system from the same vendor as your warehouse management system. Thus, you can run your manual and automated processes in the warehouse with the same logic. The fully integrated solution also allows for easier software updates, faster response times to changes, and a single point of contact for product support.

Summary

Automated warehouses will continue to grow. A well-integrated automation solution is more valuable than separate isolated systems – and the WCS helps you achieve that. A good WCS software supports your automation expansion efforts and allows you to manage your automation solutions through a single system – making your life easier and your business more profitable.

Are you currently exploring options?

We help you gain full traceability and control over your warehouse automation machinery with Astro WCS®, our warehouse control software. Its plug-in architecture ensures smooth integration with any automation vendor, giving you the freedom of choice and flexibility to transform or expand your operation.

EXPLORE ASTRO WCS®

FAQs

What is a Warehouse Control System (WCS)?

A WCS is software that manages how tasks are performed by automated warehouse equipment—such as conveyors, picking robots, and cranes—to ensure seamless operations.

How does a WCS differ from a WMS?

A WMS oversees overall warehouse operations, such as inventory management and order processing. A WCS, on the other hand, acts as a flow control engine and load balancer for automation equipment.

When do I need a WCS?

A WCS is essential when your warehouse includes multiple automation systems that require integration and real-time management, especially as complexity increases.

What are the key functions of a WCS?

- Equipment Coordination: Controls automated systems like AGVs and sorters.

- Routing and Flow Control: Optimizes item movement within automated zones.

- Load Balancing: Ensures efficient use of equipment.

- System Monitoring: Tracks performance and handles exceptions in real-time.

How does a WCS improve warehouse efficiency?

It reduces bottlenecks, ensures seamless equipment integration, and maximizes ROI on automation through improved speed and accuracy.

Can a WCS integrate with my WMS?

Yes, some form of integration between WMS and WCS is always necessary for smooth operations. If both systems come from the same vendor, additional benefits include unified logic for manual and automated processes, simplified updates, faster response to changes, and a single point of contact for support.

Is a WCS scalable?

Modern WCS solutions are scalable, with plug-in architectures that allow integration with new equipment and vendors as your automation needs grow.

What does a Warehouse Control System (WCS) cost?

The cost of a WCS depends on factors like warehouse size, system complexity, level of automation, and integration needs. While advanced systems may require a higher initial investment, the ROI comes from reduced downtime, improved resource utilization, and increased operational efficiency. For a tailored estimate, consult your software provider.